Production Explorer Tabs

How to Navigate: Click on Production > Production Explorer > Tabs

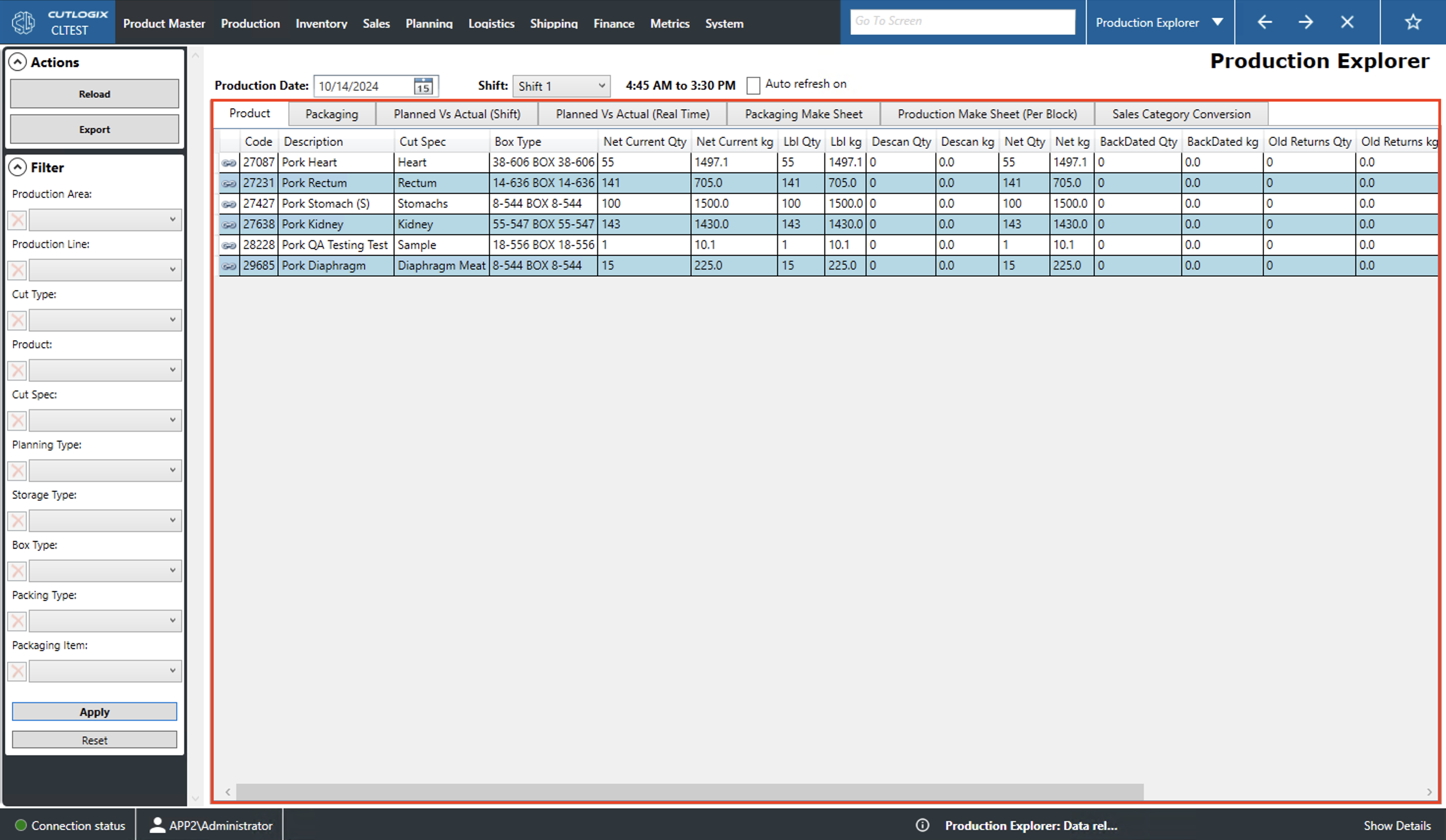

Product Tab

- Code: A unique identifier for the product.

- Description: A name/description of the product.

- Cut Spec: Indicates the cut specification (cut spec) used for the product.

- Box Type: Indicates the type of box that is used to package this cut spec.

- Net Current Qty: The number of units of product that have currently been produced on the selected day (i.e. boxes, cases, pieces, etc.).

- Net Current kg: The weight, in kilograms, of product produced minus the weight of its packaging.

- Lbl Qty: The number of products labelled on the selected day.

- Lbl kg: The weight, in kilograms, of product labelled on the selected day.

- Descan Qty: The number of product labels that were deleted or descanned from the manufacturing execution system (MES).

- Net Qty: Number of products labelled minus the number of products descanned.

- Net kg: The weight of the products labelled minus the weight of the products descanned.

- BackDated Qty: The number of products that were labelled today but cut on a previous day.

- BackDated kg: The weight of the products that were labelled today but cut on a previous day.

- Old Returns Qty: The number of backdated products that were descanned on this shift.

- Old Returns kg: The weight, in kg, of the backdated products that were descanned on this shift.

- Consumed Qty: The number of cartons of product that have been consumed from inventory as raw materials for the production of another product.

- Consumed kg: The weight, in kilograms, of product that have been consumed from inventory as raw materials for the production of another product.

- Piece Count: The total piece count of the product produced on the selected day

- Estimated Piece Count: Whether or not the product uses an estimated piece count

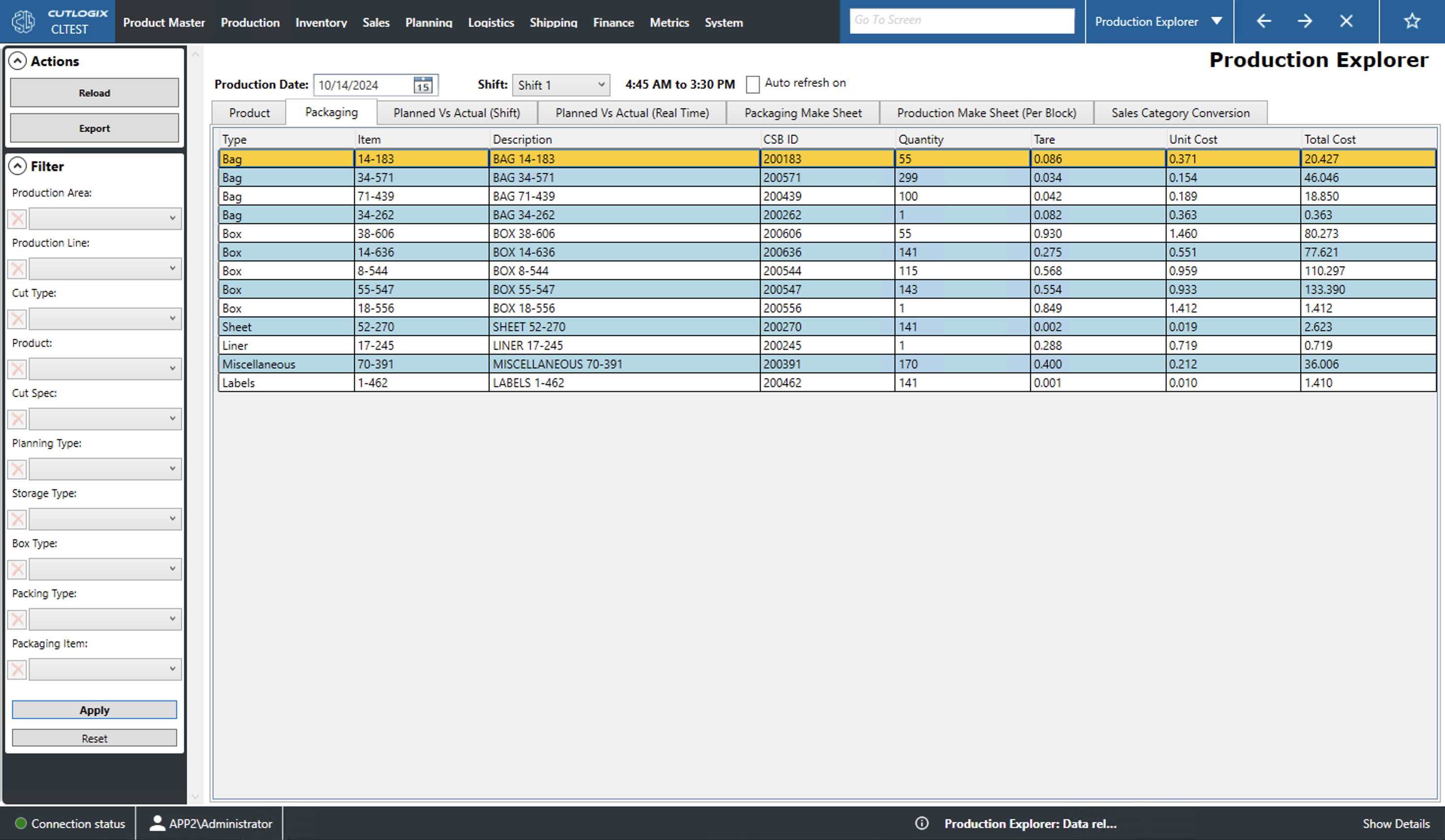

Packaging Tab

- Type: Indicates the type of packaging item used (bag, COV bag, etc.).

- Item: Indicates the packaging item ID number.

- Description: Name/description of the packaging item.

- CSB ID: This is the Computerized Scale Batch Identifier. This number is a unique identifier used to track batches of packaging items.

- Quantity: The number of units of this packaging item used on this shift.

- Tare: The weight of a packaging item used on this shift.

- Unit Cost: The cost per unit of a packaging item.

- Total Cost: The total cost of the particular type of packaging item used on this shift.

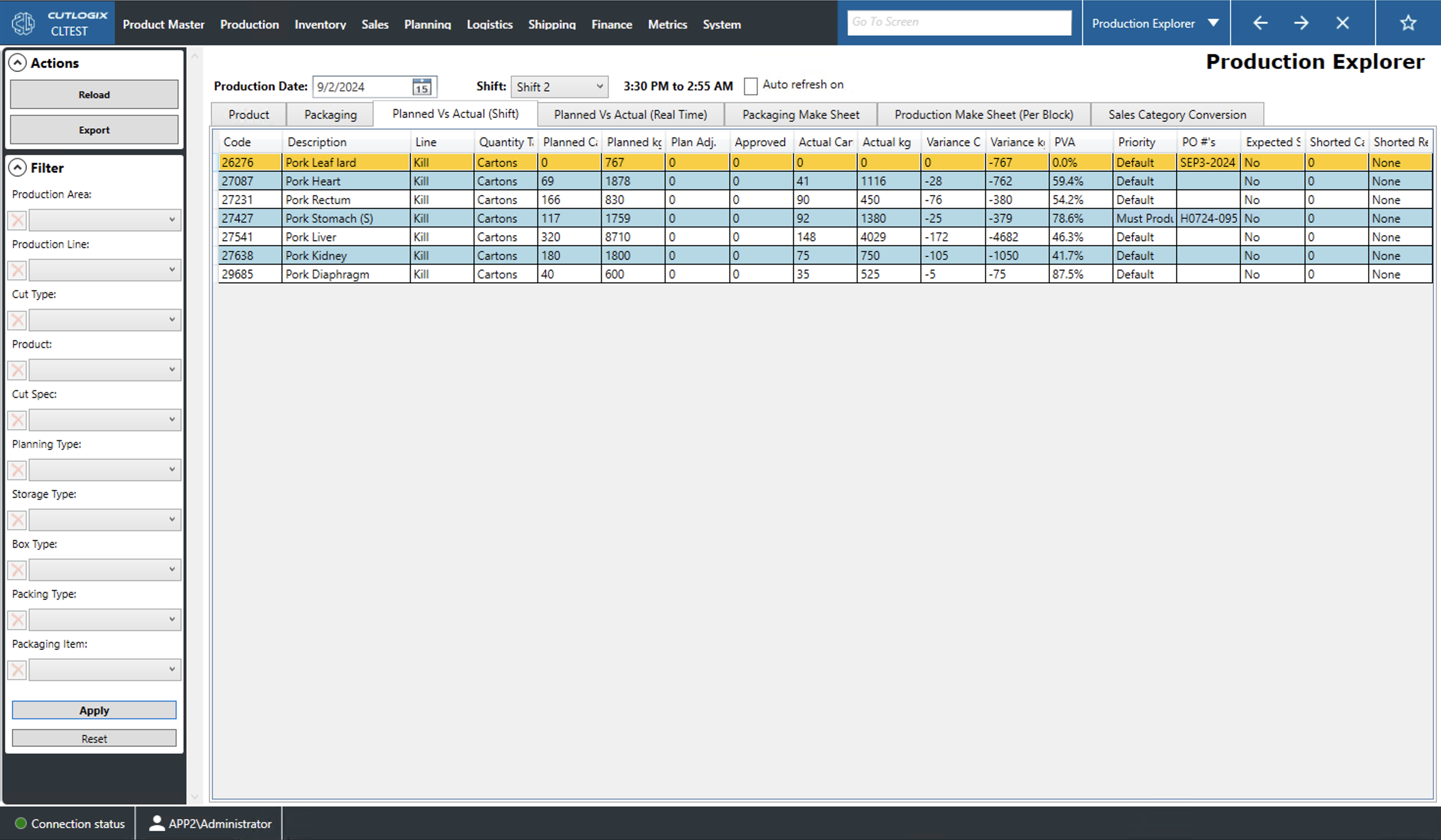

Planned vs Actual (Shift) Tab

The numbers on this page are calculated with respect to the production plan for the whole shift.

- Code: A unique identifier for the product.

- Description: The product's name/description.

- Line: The production line on which this product is produced (Shoulder, Butt, Ham, etc.).

- Quantity Target: Indicates whether the weight or the number of cartons is the production metric that must be satisfied.

- Planned Cartons: The number of cartons that is planned to be produced on this shift.

- **Planned kg** The weight, in kilograms (kg) of product that is planned to be produced on this shift.

- Planned Adj.: Suggested number of cartons to adjust the production of this product by.

- Approved Adj.: Approved number of cartons to adjust production of this product by.

- Actual Cartons: The number of cartons that have been produced so far on this shift.

- Actual kg: The weight, in kg, of a product that has been produced so far on this shift.

- Variance Cartons: The difference between the planned and actual cartons of a product. Positive number means the actual is ahead of the planned, negative means it is behind and zero means that the actual matches the plan.

- Variance kg: The difference between the planned product weight, in kg, of a product and its actual weight. A positive number means the actual is ahead of the planned, negative means it is behind and 0 means that the actual matches the plan.

- PVA: This is a percentage that shows how close actual production is to the planned number. Here are some examples:

- 100% means actual production exactly matches planned

- 95% means that actual production is only 95% of planned

- 15% means that actual is 15% over what was planned

- Priority: Indicates the production priority of the product.

- Must produce: This product must be produced according to plan on this shift.

- Up to: This product can be produced up to the planned number but not beyond it.

- PO #'s: Product order numbers (PO #'s). These numbers are used to track what customers have ordered and in what amounts.

- Expected Short: Indicates how much actual production is intended to be short of planned.

- Shorted Cartons: Indicates how much actual production is currently short of planned.

- Shorted Reason: Indicates the reason for the the intentional short.

Planned Vs Actual (Real Time) Tab

The numbers on this page are calculated with respect to what has been produced relative to what should have been produced by the current point in the day.

- Code: A unique identifier for the product.

- Description: Name/description of the product.

- Line: Production line on which the product is processed.

- Planned Cartons: Number of cartons of the product that are planned to be produced.

- Plan Adj.: The amount of cartons that the planned number has been adjusted by.

- Actual Cartons: Actual number of cartons produced by the current point in the day.

- Variance Cartons: Difference between the number of cartons planned and the actual number of cartons.

- PVA %: Shows the percent of the planned cartons that have been produced. Here are some examples:

- 100% means that actual production matches planned

- 80% means that actual production is equal to 80% of planned

- -10% means that actual production is over planned by 10%

- Priority: Indicates the production priority of the product.

- Must produce: This product must be produced according to plan on this shift.

- Up to: This product can be produced up to the planned number but not beyond it.

- PO #'s: Product order numbers (PO #'s). These numbers are used to track what customers have ordered and in what amounts.

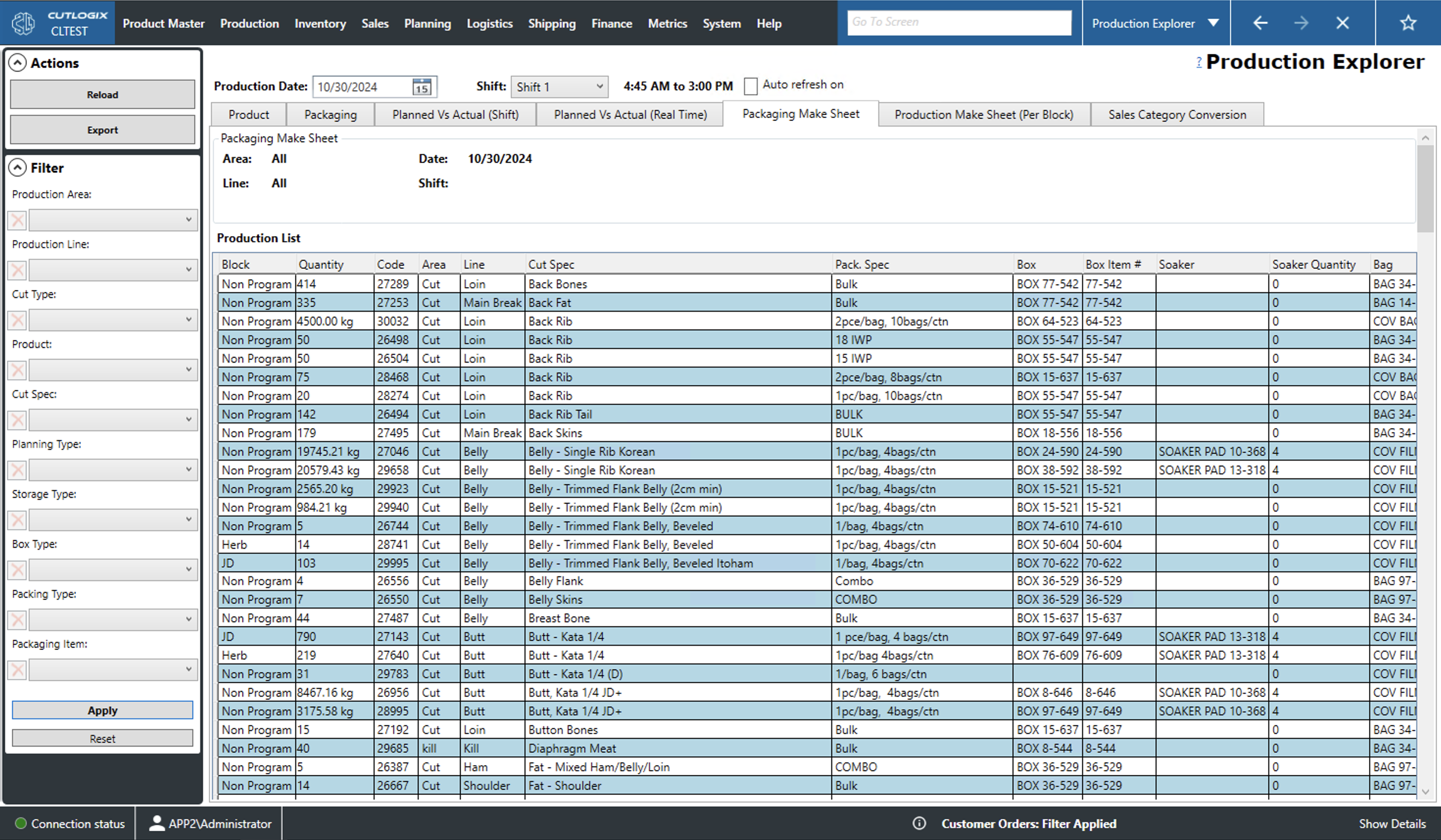

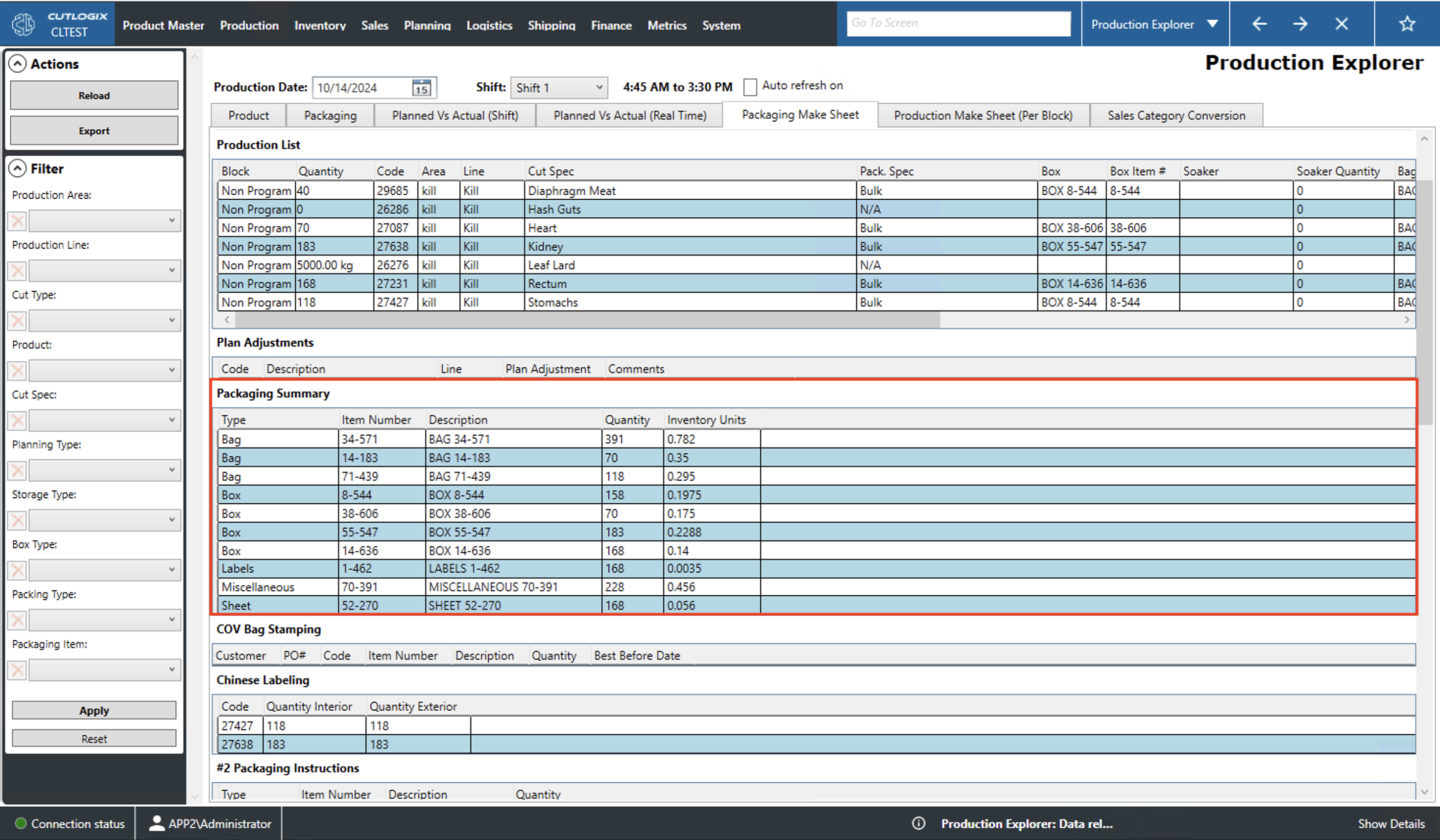

Packaging Make Sheet Tab

- Packaging Make Sheet: Shows all products in the production plan for the current shift alongside the packaging materials they require.

- Area: Indicates the production area in which the products displayed are made (i.e. kill, cut, or all).

- Line: Indicates the production line on which the products displayed are made (i.e. ham, shoulder, butt, etc.).

- Date: The production date for the data displayed.

- Shift: The shift for the data displayed.

Packaging Make Sheet Tab: Production List

- Block: Indicates the hog block in which the product is made on the selected day.

- Quantity: The quantity of this product that is planned to be produced this shift.

- Code: A product's unique identifier.

- Area: The production area of the plant in which this cut is produced (i.e. kill, cut, etc.).

- Line: The production line on which this cut is produced (i.e. ham, shoulder, butt, etc.).

- Cut Spec: The cut specification (cut spec) produced for this product.

- Pack. Spec: How this product is to be packaged. For example: 1 piece/bag.

- Box: Type of box/carton used.

- Box Item #: Unique identifier for the box/carton.

- Soaker: Type of soaker pad used.

- Soaker Quantity: Number of pads used.

- Bag: Type of bag used.

- Bag Item #: Unique identifier for the bag used.

- Bag Quantity: Quantity of bag used.

- Sheet: Type of cryovac sheet used.

- Sheet Quantity: Number cryovac sheets used.

- Divider: Type of product divider used.

- Divier Quantity: Number product dividers used.

- Chinese Inner/Outer: Whether or not this product requires an inner/outer Chinese label as part of its packaging.

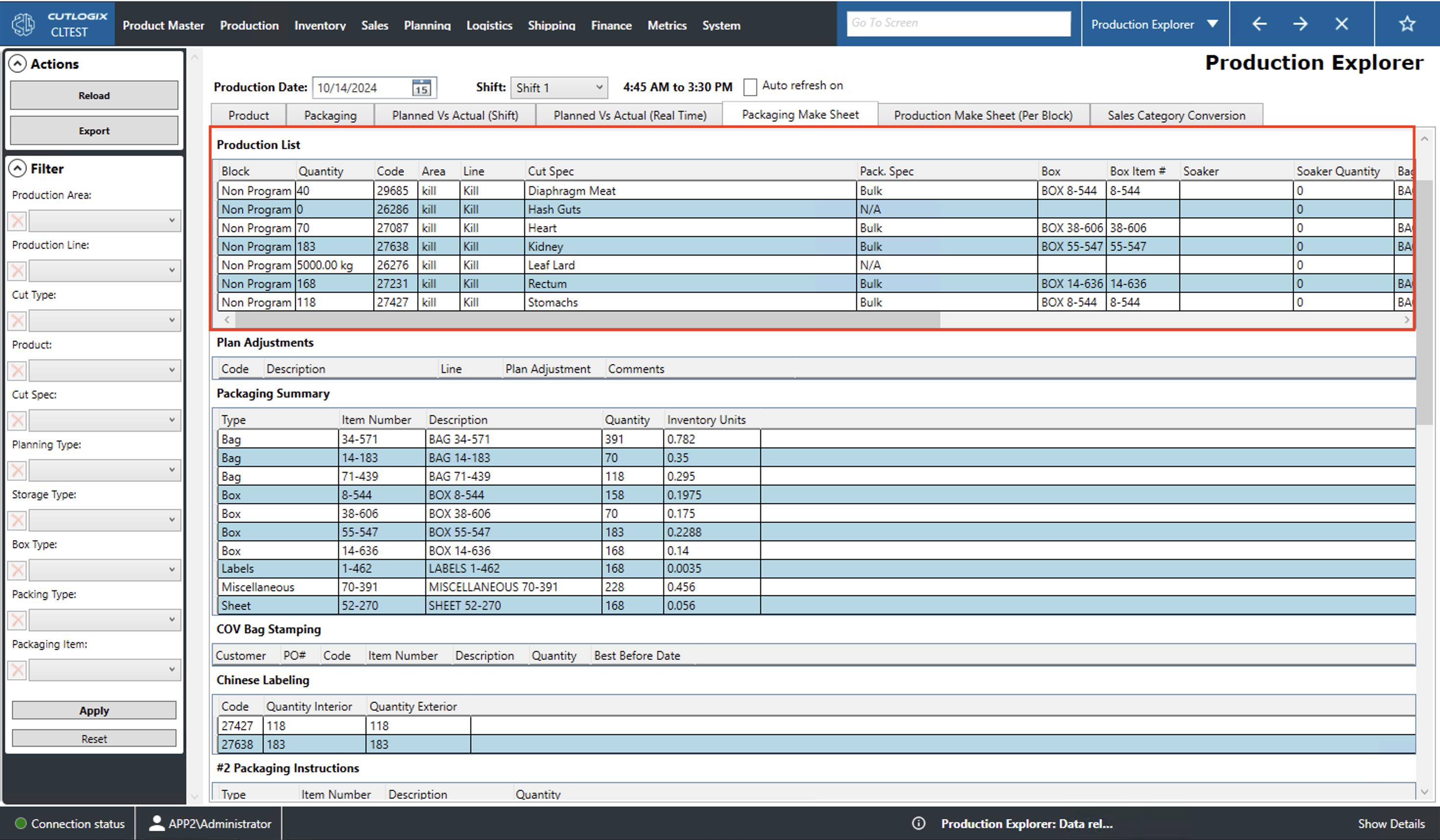

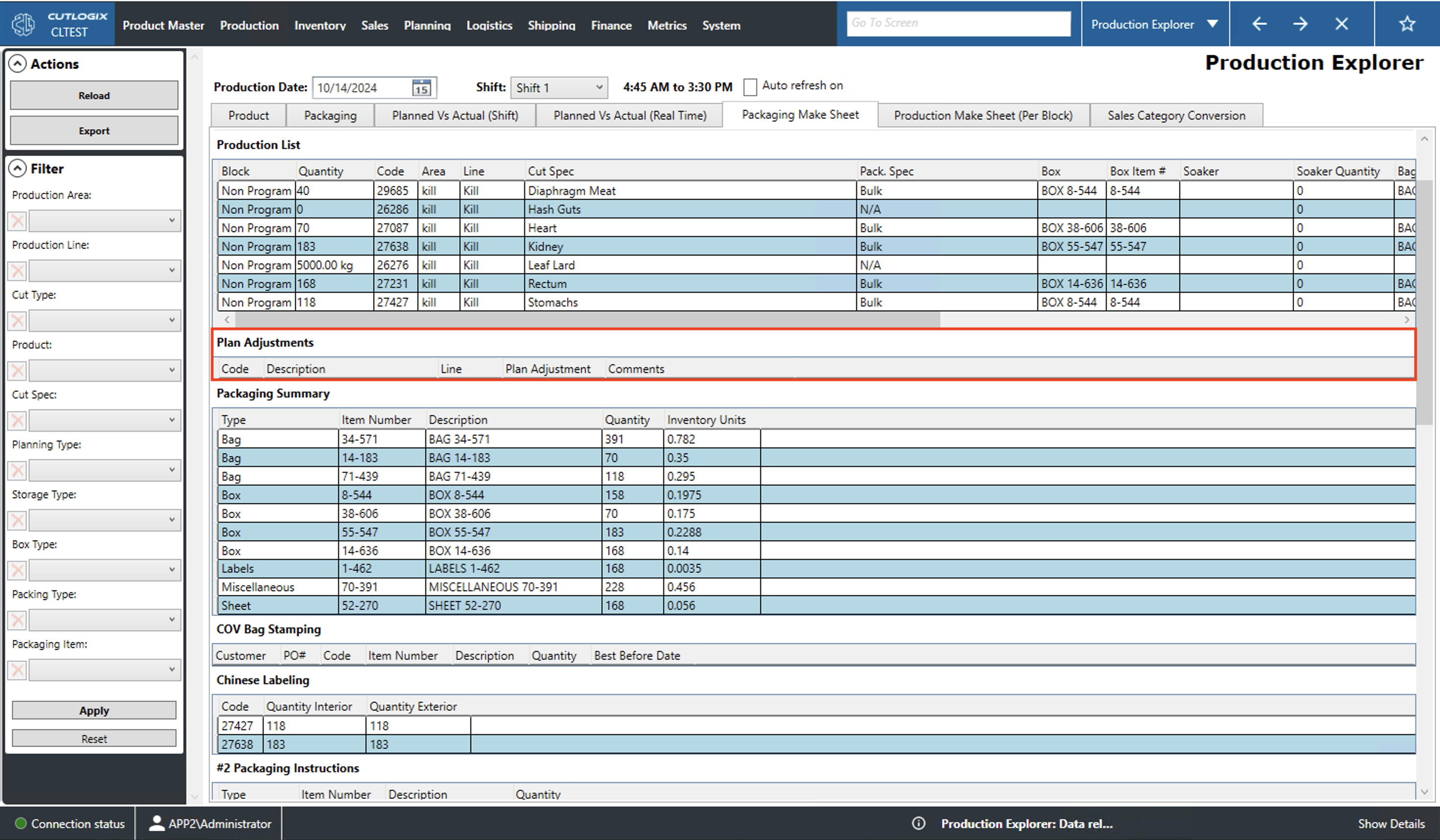

Packaging Make Sheet Tab: Plan Adjustments

Products that were added as adjustments to the product plan.

- Code: Unique identifier for the product.

- Descripton: The name/description of the product.

- Line: The production line on which this product is made.

- Plan Adjustment: The number of units of product that the production plan was adjusted by.

- Comments: A space for comments on the adjustments were made.

Packaging Make Sheet Tab: Packaging Summary

Shows a summary of the packaging materials required by the production plan without the associated products.

- Type: Type of the packaging material (bag, box, soaker, etc.).

- Item Number: Unique identifier for the packaging material.

- Description: The name/description of the packaging material.

- Quantity: The total amount of that packaging material required for the current shift.

- Inventory Units: The quantity of the packaging materials needed translated into pallets of inventory.

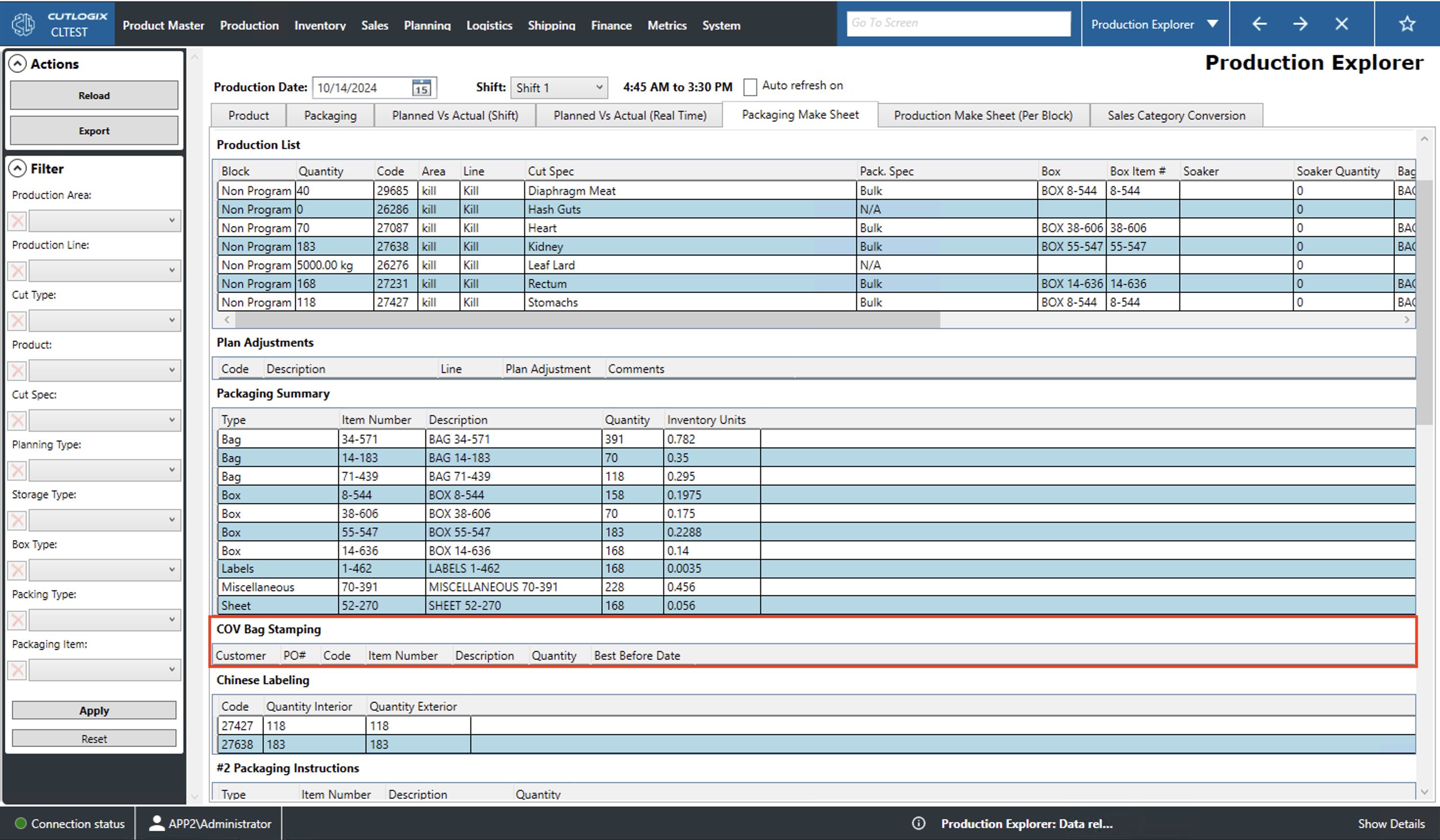

Packaging Make Sheet Tab: COV Bag Stamping

Indicates products that require best before dates on their cryovac packaging.

- Customer: Name/description of the customer.

- PO#: The Product Order number (PO#) of the order that this product is being made for.

- Code: Unique identifier for the product.

- Item Number: Unique identifier for the packaging.

- Description: Name/description of the packaging item.

- Quantity: The amount of the packaging item.

- Best Before Date: The best before date to be stamped on the packaging.

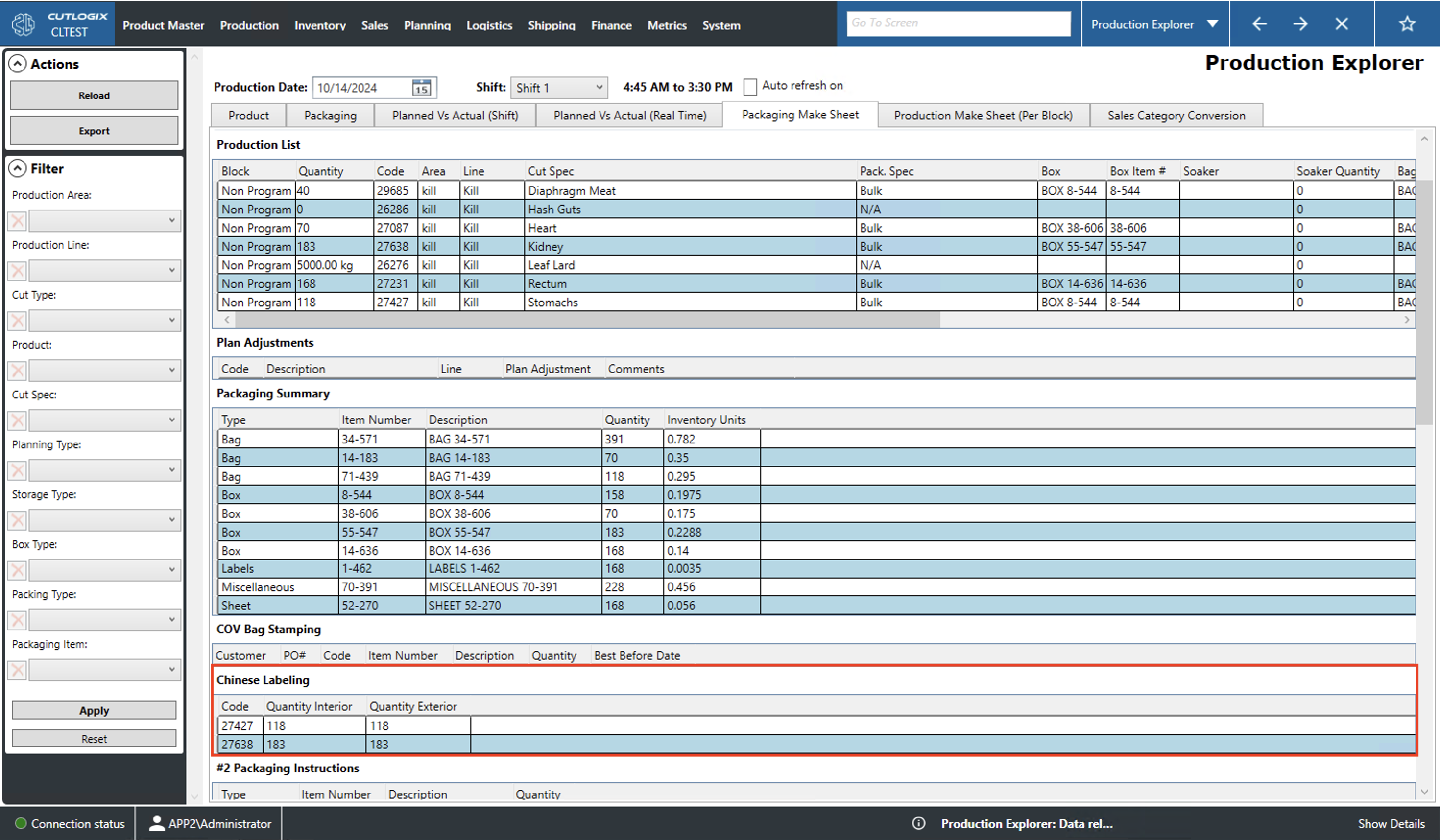

Packaging Make Sheet Tab: Chinese Labeling

Indicates information about products that require Chinese labels.

- Code: Unique identifier for the product.

- Quantity Interior/Exterior: Amount of inner/outer Chinese labels required for that type of product.

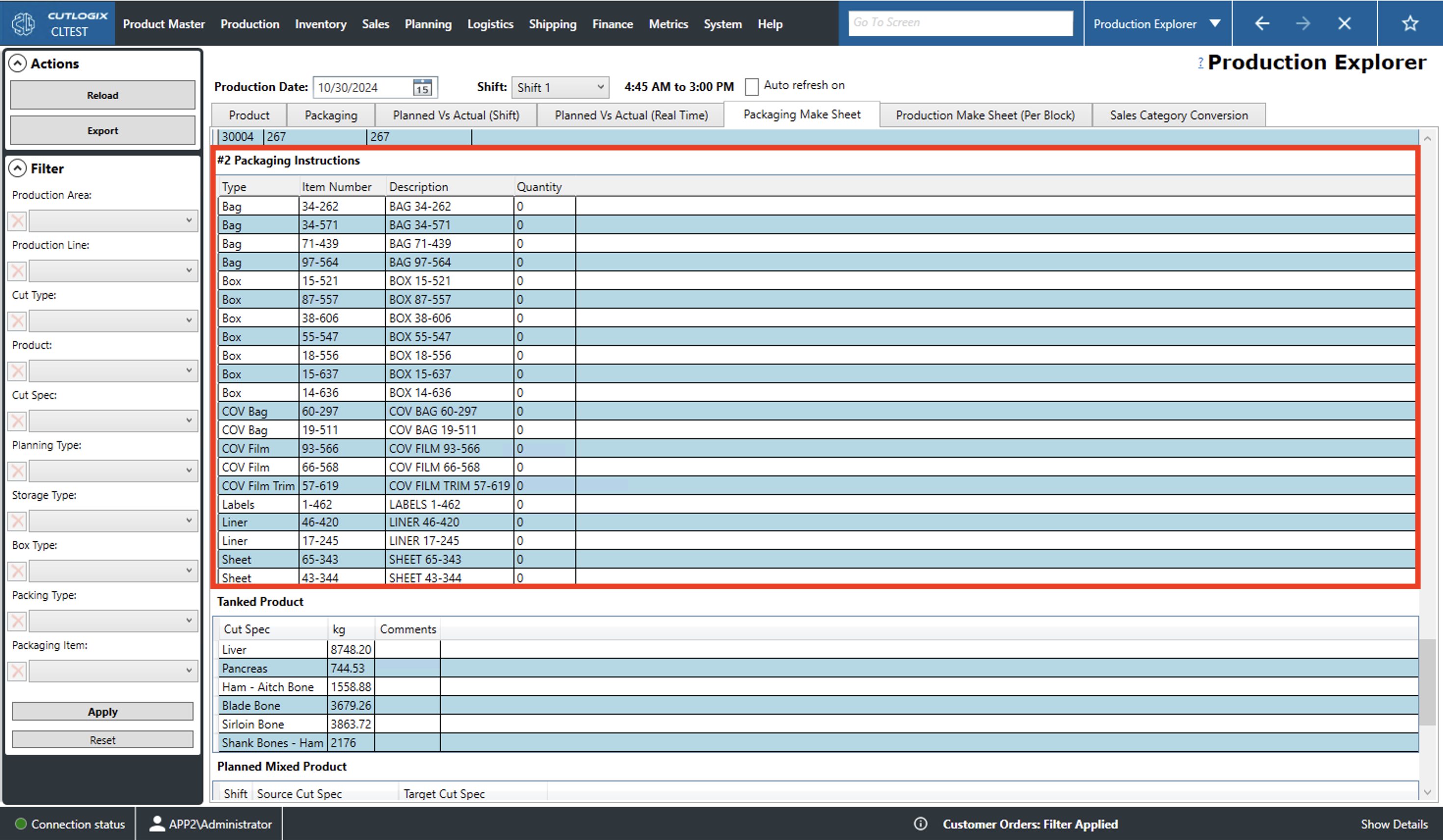

Packaging Make Sheet Tab: #2 Packaging Instructions

Contains information about packaging product that was downgraded due to quality concerns.

- Type: Type of the packaging material (bag, box, soaker, etc.).

- Item Number: Unique identifier for the packaging material.

- Description: The name/description of the packaging material.

- Quantity: The total amount of that packaging material required for the current shift.

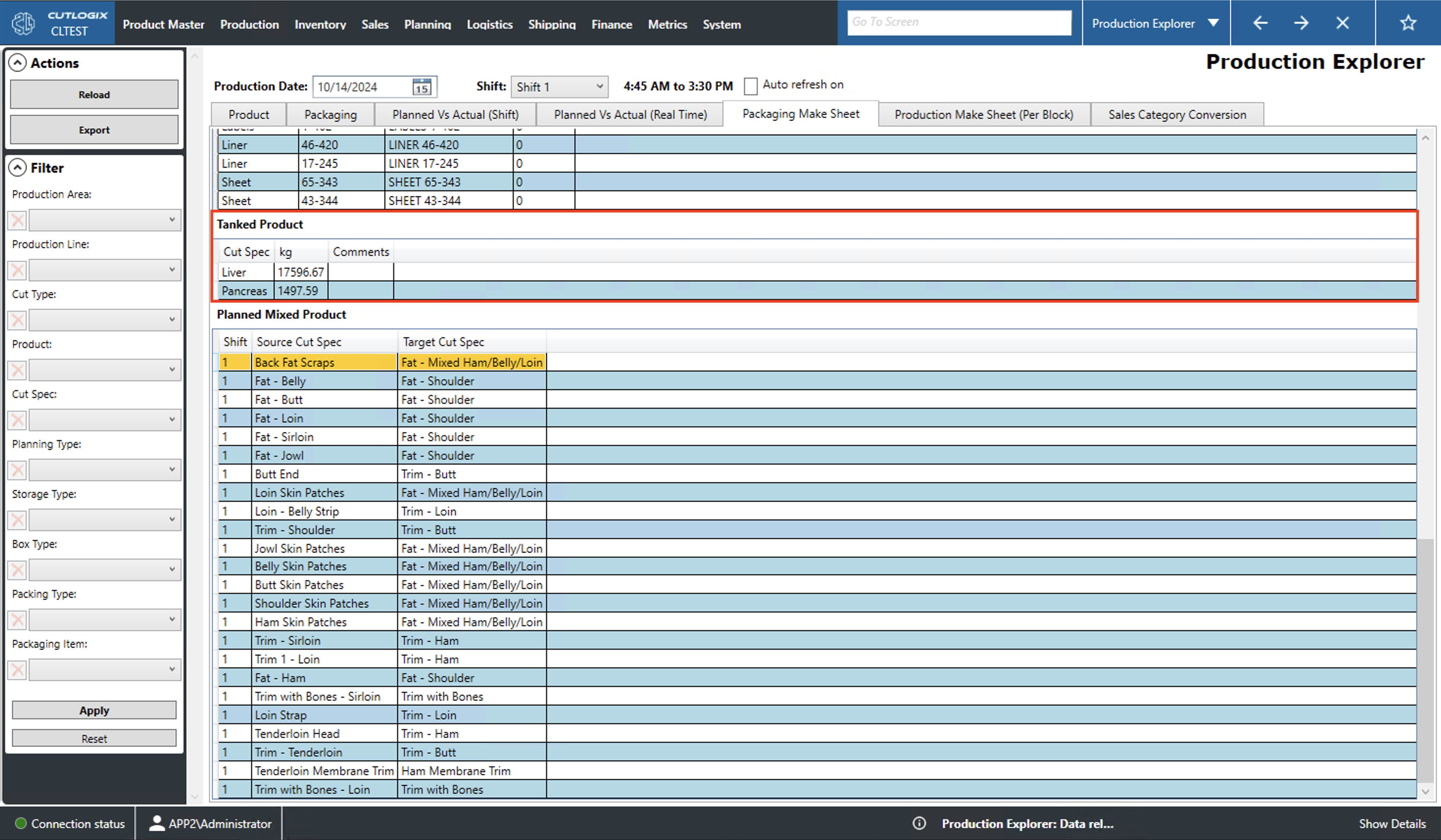

Packaging Make Sheet Tab: Tanked Product

Contains information about products that is planned to be discarded.

- Cut Spec: The cut spec of the discarded product.

- kg: The weight, in kilograms, of the discarded product.

- Comments: A space for comments on the discarded product.

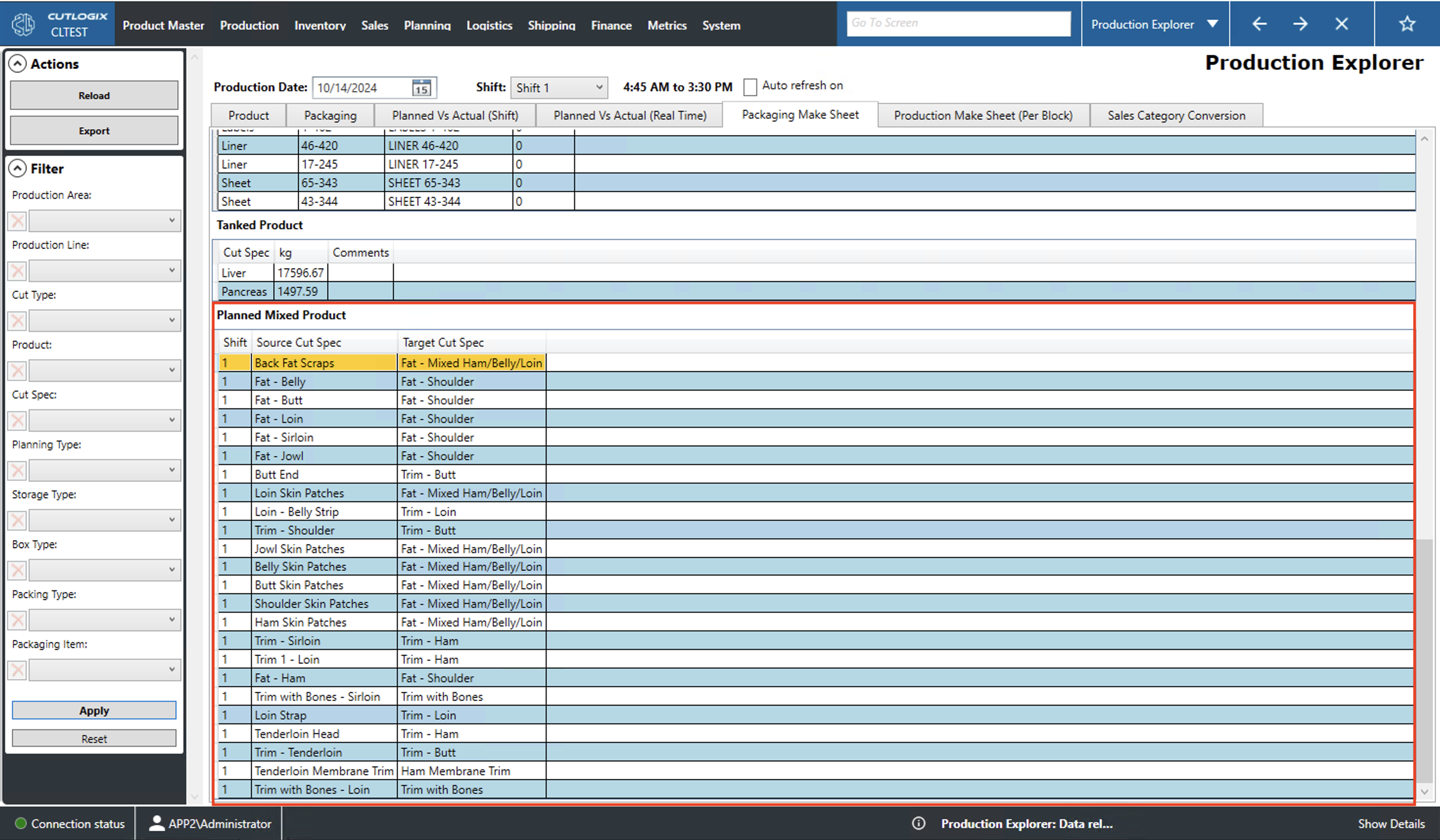

Packaging Make Sheet Tab: Planned Mixed Product

Information about products that will be mixed together.

- Shift: The shift on which this product is planned to be produced.

- Source and Target Cut Spec: These are the cut specs that will be mixed together to make the mixed product for sale. These will be sold as the target cut spec.

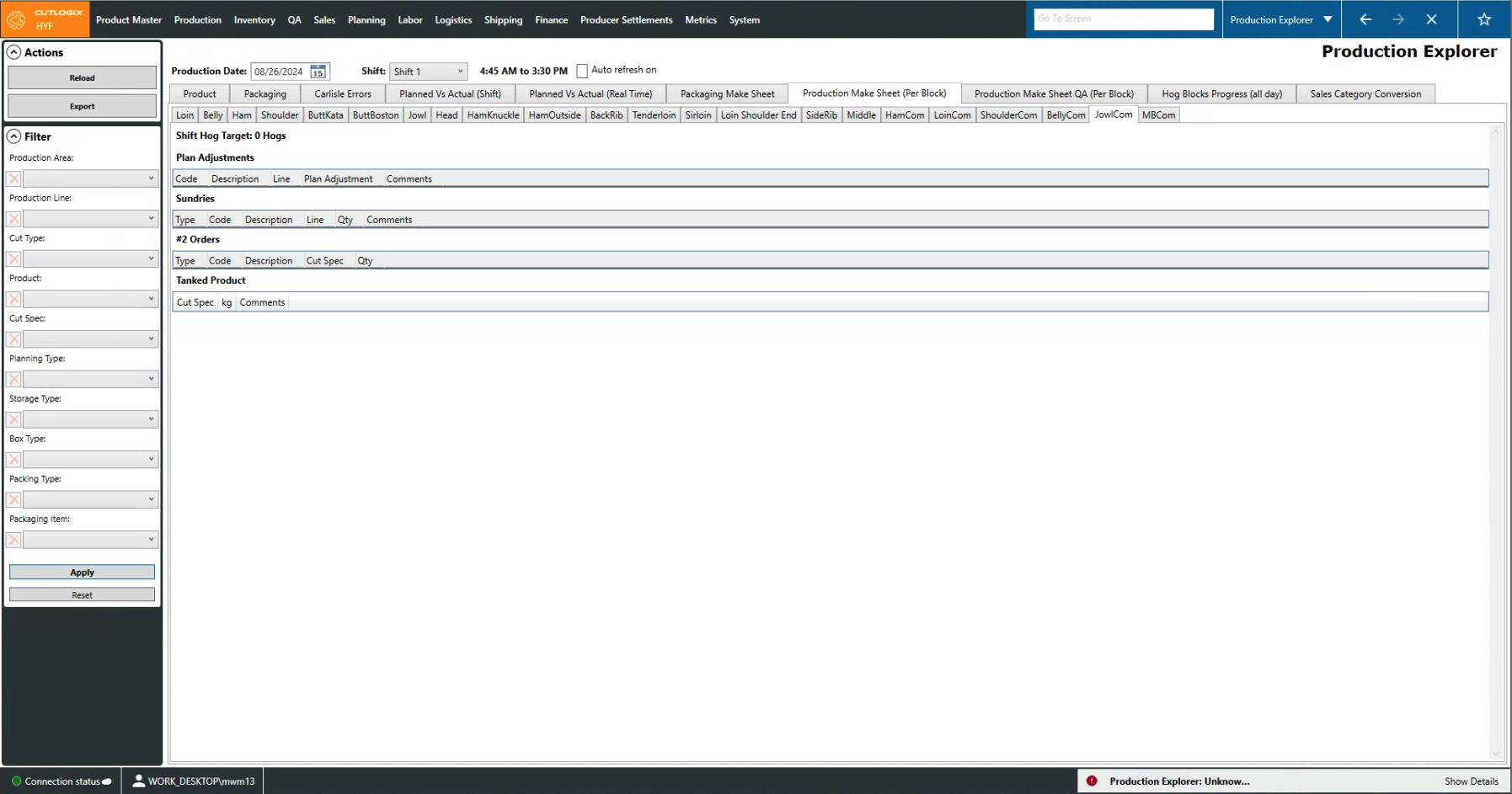

Production Make Sheet (per block) Tab

- Shift Hog Target: This number shows how many carcasses are planned to be processed on the current shift.

- Hog Blocks: This section will be populated with time blocks during which particular types of hogs will be processed. The products that are to be produced in that time block will be listed here. These blocks are organized into specific tabs based on the main type of cut (Loin, Belly, Ham, etc.). This section will also display unscheduled blocks for plan adjustments, sundries/credits (leftover from creating other cut specifications), #2 orders (products downgraded based on quality) and Tanked Product (product to be discarded).

- Type: Refers to where this product falls in the product cascade.

- Primary: Products that are the most valuable but have a low pass rate.

- Accum: Products with a higher pass rate but lower value. These are products that the primary product can be downgraded to.

- Default: The least valuable product that the primary product can be downgraded to but it has a 100% pass rate.

- Code: Unique identifier for the product.

- Planned Cartons (Pieces): The initial number is the amount of planned cartons and the number in brackets is the number of pieces per carton.

- Description: Name/description of the product.

- Cut Spec: The cut specification (cut spec) for this product.

- Product Cooling: The required cooling type for this product (fresh, cooled or frozen).

- Pass Rate (Priority): The rate at which pieces can be sold as this product. For example, 15 means that 15% of the pieces that come down the production line meet the quality standards for this product.

- Conv. Rate: The rate at which this product can be converted from a higher grade product into a lower grade but sellable product.

- Sized Rate: The rate at which these products pass size requirements.

- Comments: A space for comments on the the particular product.

- Plan Adjustments: Block showing adjustments to the production plan.

- Code: Unique identifier for the product.

- Description: Name/description for the product.

- Line: The production line on which the product is produced (Loin, Belly, Ham, etc.).

- Plan Adjustment: The number of units of product that the production plan was adjusted by.

- Comments: A space for comments on the plan adjustments.

- Sundries: Block showing the anticipated sundries/credit byproducts that will be produced when making other products.

- Type: Refers to where this product falls in the product cascade.

- Code: Unique identifier for the product.

- Description: Name/description of the product.

- Line: The production line on which the product is produced (Loin, Belly, Ham, etc.).

- Qty: Anticipated quantity of the relevant credit/sundry.

- Comments: A space for comments on the sundries/credits.

- #2 Orders: A block giving information about the anticipated #2 products produced from the hog blocks above.

- Type: Refers to where this product falls in the product cascade.

- Code: Unique identifier for the product.

- Description: Name/description of the product.

- Cut Spec: The cut specification that the #2 product is downgraded from.

- Qty: Anticipated quantity of the relevant #2 product.

- Tanked Product: A block showing the anticipated discarded product from the hog blocks above.

- Cut Spec: The cut specification that was discarded.

- kg: The anticipated weight of the discarded cut specification.

- Comments: A space for comments on the discarded product.